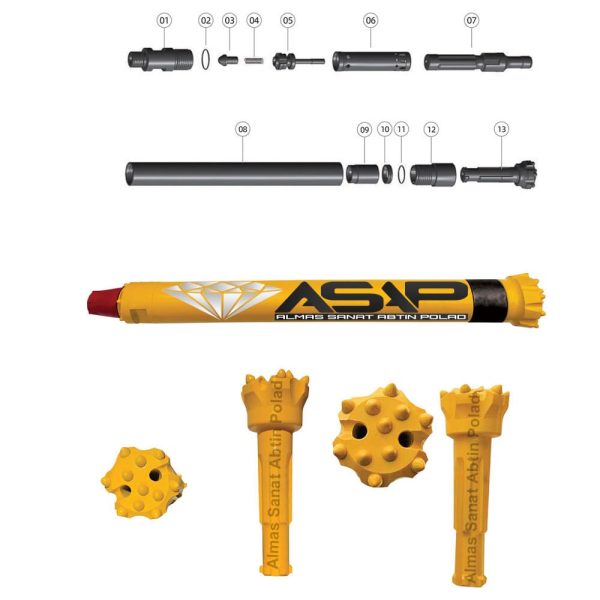

Low-Pressure Drilling Hammer

Almas Sanat Abtin Poulad is a manufacturer and importer of low-pressure drilling hammers, high-pressure drilling hammers, and RC (Reverse Circulation) hammers with excellent quality and competitive prices. The company ships its products nationwide, allowing you to purchase directly from the factory and benefit from competitive pricing. By buying from Almas Sanat Abtin Poulad, you will receive the best drilling equipment with guaranteed quality and affordable prices. For more information and to purchase products, contact us.

051-36513317-8

09153119517

09030209517

Low-Pressure Drilling Hammer (Low-pressure DTH Hammer)

ow-pressure drilling hammers are typically designed for drilling in soft rocks and surface mines. These hammers are the best choice for projects that require fast drilling and lower energy consumption

Features

- Low air pressure (5 to 10 bar): Due to the low pressure, they consume less energy.

- High drilling speed: Due to low pressure, these hammers can drill quickly in soft to medium rocks.

- Reduced tool wear: Using low pressure, these hammers have a longer service life.

- Suitable for surface mines: For mines with shallow depths, these hammers are an ideal choice.

Suitable rocks and mines

- Soft to medium rocks: including limestone, sandstone, shale, and alluvial rocks.

- Sand and gravel mines: for drilling in surface mines and fine-grained rocks.

- Shallow mines: suitable for drilling in low-depth mines.

Low-pressure hammer specifications table

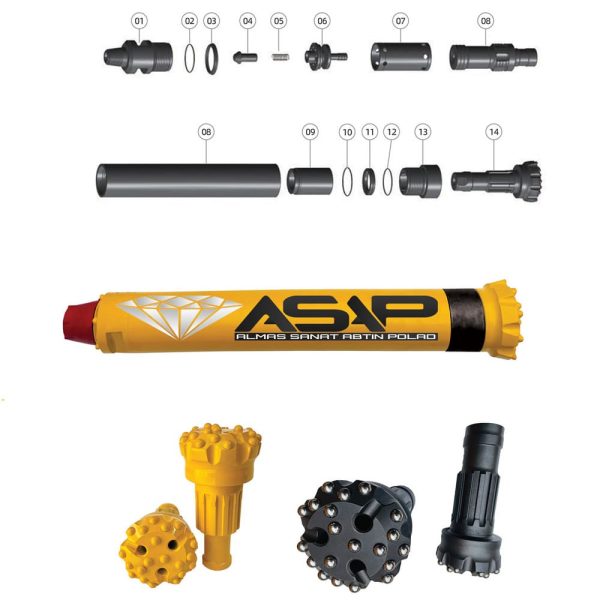

High-pressure DTH Hammer

High-pressure drilling hammers are designed for tougher projects and drilling in hard rocks and deep mines. These hammers can drill under more challenging conditions and are suitable for more complex projects.

Feature

- High air pressure (15 to 30 bar): These hammers require higher pressure, resulting in greater drilling force.

- Greater drilling force: suitable for drilling in hard and resistant rocks.

- Longer performance: these hammers perform better in deep drilling and tougher conditions.

- Higher energy consumption: due to higher pressure, these hammers consume more energy.

Suitable rocks and mines

- Hard rocks: including granite, basalt, igneous rocks, and metamorphic rocks

- Deep mines: for drilling in high-depth mines or challenging conditions.

- Tunnel and complex project drilling: suitable for underground drilling conditions.

Click here to purchase a high-pressure drilling hammer

Comparison of low-pressure and high-pressure drilling hammer

| Feature | Low-pressure drilling hammer | High-pressure drilling hammer |

|---|---|---|

| Required air pressure | 5 to 10 bar | 15 to 30 bar |

| Suitable rocks for drilling | Soft to medium rocks (limestone, sandstone, shale) | Hard rocks (granite, basalt, igneous rocks) |

| Drilling speed | High speed in soft rocks | Lower speed compared to low-pressure hammers |

| Energy consumption | Lower energy consumption | Higher energy consumption |

| Drilling force | Lower force compared to high-pressure hammers | Greater drilling force |

| Suitable for depth | Shallow depths and surface drilling | Greater depths and more challenging projects |

| Durability and wear | Lower wear | Higher wear, but longer lifespan |

| Suitable mines | Surface mines (sand and gravel, limestone, sandstone) | Deep mines (granite, basalt, igneous rocks) |

Conclusion

- Low-pressure drilling hammers are suitable for mines with softer rocks and surface projects. These hammers are used in sand and gravel mines and limestone rocks due to lower energy consumption and higher drilling speed.

- High-pressure drilling hammers are suitable for hard and resistant rocks such as granite and basalt, as well as deep mines due to their greater drilling power. These hammers are typically used in underground mines and deep drilling projects.

Based on your project needs, you can make the right choice between low-pressure and high-pressure drilling hammers.